×

×

The die cast is the process of casting metal items with use of mold. This process typically consists of melting the metal down, and then slowly pouring it into a mold. After the metal is poured in and it cools down, it turns hard and becomes into this very specific shape that has been made with the mold. A versatile method, which is used in a variety of industries to create car parts, kitchen tools and the fun toys for kids. Since die casting is a complex process with various parts and factors, there can be many different aspects of the cost.

The most important part of the die casting process is certainly mold. It is how the metal takes its shape while cooling that gives a mold. In steel which is very strong and that never breaks easily. It takes a lot of energy and resources to make these molds. Plus, technical workers are also needed to create and make the molds. All of this work means that the cost to produce a mold is a major, but not Unprecedented, expenditure in comparison with total expenditures in Boqiao Gravity die casting machines process.

Businesses that utilise Die Casting well always save on cost wherever they can. There are many ways that can be done. Using recycled materials in the production line is just one of them. Thus, they must recycle old materials, rather than creating everything from scratch which in turn brings costs down. You may also choose to recycle materials as they can be significantly less expensive than new raw material with no other negatives necessarily associated with them.

Along with recycling materials or designing reusable molds, companies might also come up with new strategies to aid in Boqiao Low Pressure die cast machines. A company could also consider spending a large sum on the latest technology that will minimize energy consumption for making molds. Both facilities have lowered their energy use, thereby saving money in the long term by utilizing equipment or practices that are more efficient.

The cost of operating with the die casting process can differ according to many different factors. A determining factor is the size of one s output. Larger objects in general are made with more materials which drives the cost up. The complexity of the part is another major factor. The more detail a component has, the harder it is to manufacture. These Boqiao Aluminum casting parts complex tend to be difficult and labour intensive to manufacture, therefore a higher cost is required for their creation.

One other thing that might be important is the metal coming used Metals with various properties and Costs. This helps explain why some metals are a very good solution for being die-cast properties of aluminum or light weight would be easily influenced in an otherwise difficult to work with metal. But the aluminum is also sometimes more costly when compared with other metals, example zinc might be cheaper but can it impart some unique properties in BQ quenching furnace that is why you use it in production.

Companies looking to determine how they should proceed with die casting often weigh what it costs BQ melting furnace for different materials and methods. For example, they can compare costs between the use of zinc and aluminum. Since every material has its strengths and weaknesses, organizations must choose the right trade-offs. There is also the cost of a single use mold Vs. multiple times biggest this comes down to what you want and need in your project.

Nanjing BoQiao Machinery Co., Ltd is a Die casting cost, manufacturing, selling manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer our customers all kinds of overall solutions and turnkey projects, including technical consulting, equipment selection mold manufacturing design, process development, operating training, and more. Our products can create an added value for our customers. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.

Our journey into the field of casting began in 1979 with sales of casting materials that laid the groundwork for our experience as well as our market position Over the years we have built lasting relationships with our clients through offering high-quality products and excellent service In 1997 we expanded our services to include manufacturing of electric furnaces for industrial use This move was a strategic one that allowed us to offer more complete solutions for our clients and satisfy their increasing demand for high-quality reliable heating equipment At this point our commitment to quality and innovative thinking made us stand out from the competition In Die casting cost we had further expanded into the manufacture of casting machines We were able to provide the full spectrum of solutions for casting including the materials as well as machinery This enabled us to become a one-stop store for our customers with casting needs Our experience and extensive knowledge of the industry has made us a reliable partner for businesses seeking top-notch casting equipment and services We've always been devoted to customer satisfaction and continuous advancement This has driven us to evolve and adapt in a marketplace that is ever-changing

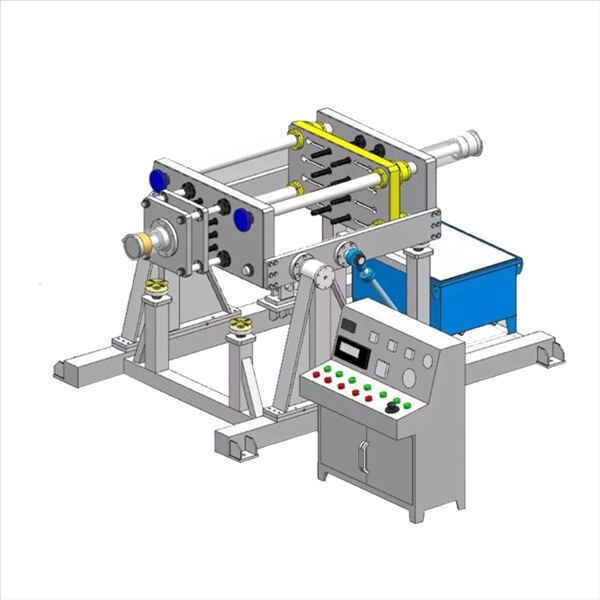

BoQiao's gravity-casting machine features small dimensions, which makes it a great choice for a variety of Die casting cost. The BoQiao gravity cast machine's compact design and high-performance make it an ideal choice for various manufacturing environments. Its reliability and value make it a valuable investment for companies looking for reliable casting solutions. It is praised by clients for its consistency in quality, easy operation and maintenance and increased productivity.

Since 1999, our company has Die casting cost and sold over 2000 units. Our company has a stellar reputation among its customers due to our reliability and quality as well as excellent customer service. In addition to selling in all cities and provinces across the nation Our products have also been offered to Southeast Asia, Africa South America, Middle East and many other locations, and have been a great success by customers. Based on the business model of win-win and cooperation, honesty and sincerity, BoQiao will continue to pursue the path of professional development and constantly improve products and services to meet the development of customers. It is essential to help customers create more value.