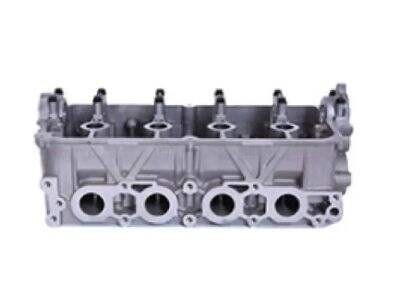

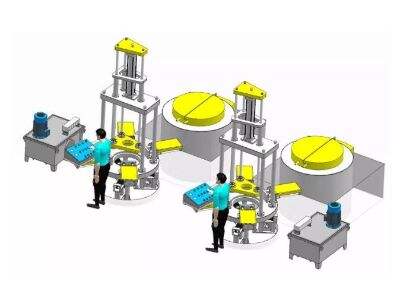

Big aluminum cans housings Big-diameter aluminum housings are key parts for many fail machines and instruments. Manufacturing these large parts is hard, because aluminum is strong but has to be light and in just the right shape. At Boqiao, we have devised a clever way to make these large aluminum housings less expensively, faster and better, using rotational casting technology. This approach allows us to make robust, smooth and dimensionally accurate aluminum parts while saving time and limiting waste. A lot of companies have a difficult time making large aluminum housings without cracks or weak points, but through rotational casting Boqiao addresses many of these problems. The process spins molten aluminum within a mold, distributing it uniformly and cooling it gently. That way the shape is perfect and the metal remains durable. We’d like to share insights about this technology, show what difficulties we encounter when producing large aluminum products and explain how does Boqiao cope with these difficulties, in order to bring high-quality aluminium every time

How Rotational Casting Technology Improves the Production of Aluminum Housing

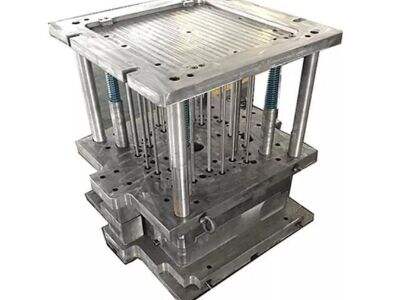

The process involves pouring molten aluminum into a hollow mold that spins slowly about two axes simultaneously; the grain structure of the metal and strength can be optimized by varying the speed and axis of rotation during cooling. This spinning causes the aluminum to move around inside the mold, pulling it into a uniform layer on all sides. The metal is forced outward as it thickens, growing into a consistent wall thickness that has no thin spots or weak points. This is especially important for large-diameter housings that require shape retention and pressure drop resistance. At Boqiao, rotational casting allows us to produce big parts fast than older ways of doing things, sand casting or die casting. Those old methods often require additional work to correct defects or fill in rough surfaces. In rotational casting, the surface is smoother coming out of the mold so less polishing or machining is required

How to Solve Common Problems in the Production of Large-Sized Aluminum Housings

It isn't really simple towards produce big aluminum real estates. One difficulty is actually handling the temperature level of steel. Awesome too quickly, as well as the light weight aluminum might break or even diminish in the incorrect locations. Its own temperature level can't lose as well gradually or it takes much a lot longer towards awesome as well as might shed stamina. At Boqiao, very attention is actually paid out towards the temperature level constantly when directing. Our team use sensing units as well as command the rate at which the steel is actually rotated so as to preserve it at exactly the appropriate temperature level. If the mold and mildew is actually wobbly, the aluminum won't load uniformly as well as you might have actually a component that is thicker on one edge or even has actually surface area problems. Designers on their own are actually solid bodily mold and mildews, as well as they confirm balance due to the opportunity of directing. Sometimes, there will certainly be actually a resonance, however our team deal with that through changing the speed of the twist, or even depend on sustains. Dimension, by itself, is a huge issue

Where to Find Long-Lasting Large-Diameter Aluminum Enclosures for Industry

When the industry demands durable and rugged housings, an aluminum housing with large diameter is usually ideal. These enclosures are employed to guard various gadgets on machinery, automobiles along with other industrial equipment. If you happen to be on the lookout for a place that provides you with such sturdy aluminum parts, it is crucial that you look for a company which has access to state-of-the-art technology and top-notch materials. We like Boqiao as a brand, one of the reasons why is that they focus on creating large aluminum housings which give you longevity. They are made from high-quality aluminum alloys that can withstand tough conditions, including extreme heat, pressure and rough handling. That is to say their housing cannot be easily broken and can provide secure protection for the machinery contained inside. Also, Boqiao specializes in manufacturing parts that correspond exactly to your requirements. Whether you need housings for huge equipment or special machinery, they can machine custom sizes and shapes to fit exactly what you are in need of

How to guarantee the best products quality in large diameter aluminum housings production

Designing large-diameter aluminum housings that both work well and run for a long time involves staying on top of the details regarding quality. At Boqiao, they understand that quality begins at the source. First, they select the appropriate grade of aluminum alloy. That’s important, because different kinds of aluminum have different strengths and properties. The alloy that Boqiao uses is strong, but also light, and this helps keep the machines efficient as well as easy to handle. Then there is the manufacturing process itself, which has to be extremely accurate. Boqiao is cast using a rotational casting process, which is also a clever way to form large aluminum pieces. This approach consists of liquid aluminum being deposited into a rotating mold. The spinning can also help distribute the aluminum uniformly within the mold, so there are no weak points or holes in the housing. This also ensures the walls of the housing are both smooth and at just the right thickness everywhere. Another critical aspect of quality is testing. Boqiao looks over each housing closely after it’s made. They search for cracks or rough patches, or any indication that the aluminum could be thinner in places

What are the Benefits of Rotational Casting for Large Custom Aluminum Enclosures

High-Quality Part Runs When a company requires multiple large aluminum housings, choosing the right production method will save time and money while maintaining quality. With rotational casting, like Boqiao does, there’s a number of advantages when making very large orders for these aluminum housings. Not only is rotational casting efficient, but there is also an advantage as to size. In it, molten aluminum is poured into a mold that turns slowly on two axes. This rotation would aid the aluminum in flowing more uniformly inside the mold. On account of this the walls of the housing are continuous in thickness and strong throughout. The result is less defects, with fewer waste. This efficiency is also what keeps costs lower when you order in large quantities, as less material is wasted and there’s less time spent fixing mistakes. Rotational casting also makes it easier to create large and complicated shapes which is an advantage. Some are also so large that they need to be relatively lightweight, yet strong, and with curves or holes that are too difficult to form with other technologies. But rotational casting, the mold of which can be engineered to create these complex forms in one go

Table of Contents

- How Rotational Casting Technology Improves the Production of Aluminum Housing

- How to Solve Common Problems in the Production of Large-Sized Aluminum Housings

- Where to Find Long-Lasting Large-Diameter Aluminum Enclosures for Industry

- How to guarantee the best products quality in large diameter aluminum housings production

- What are the Benefits of Rotational Casting for Large Custom Aluminum Enclosures

AR

AR

BG

BG

HR

HR

CS

CS

FR

FR

DE

DE

EL

EL

HI

HI

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

BN

BN

LO

LO

MN

MN

MY

MY