×

×

Die casting of car auto parts is a special way to produce very accurate metal products on high amount. This process begins with the creation of a mold, which is essentially an impression or outline that we wish to create in the metal part. The mold of Boqiao die casting machines is made very diligently so that it precisely takes on the form necessary for the part. The mold is then prepared, and hot molten metal poured into it. The mold is opened and the part removed once the metal has returned to its solid state. This enables them to make parts that are an exact fit for the car.

So what does it take to manufacture good auto die cast parts? One thing that will always change the equation is simply the mold. To produce a part that looks, fits and functions as it did on the vehicle requires an exacting mold built to precise design specifications. If the mold isn't made properly, so will be their shapes or sizes. The type of metal will also prove crucial in having a strong and nice-looking part. Choosing the right metals: after using one, starts with raw material, then the process can go on to attain comparable properties that are partly dependent upon what kinds of metals one chooses for special parts.

Auto Die Casting — Making A Mold for The Part: The mold, when prepared is then placed in the machine which injects molten metal under a high pressure into it. All of this pressure will help the metal fill all the little nooks and crannies in your mold. The liquid metal then pours into the mold, cools back down and hardens in place. Instead, the part is removed carefully from its mold and trimmed of excess metal (referred to as flash) before it can be polished for use.

Many automakers aid by the advent of auto die casting. To begin with, it enables them to produce extremely specific and complicated making that would be impossible to make by other approaches. For instance, certain parts may have irregular shapes or intricate designs that are crucial to the functioning of an automobile. Boqiao auto die cast is relatively fast and not as costly when comparing to some other means of manufacturing, it is therefore ideal for producing numerable car parts in a short time as well and whilst not being too costly.

Auto die cast parts can be found in many places of the car. Such parts can include anything from key engine components, and replacement gears in the transmission that keep your car moving on four wheels; underbody-structural replacements to support a three-point stance during heavy steering input at 100 km/h an hour — even those less substantial items as grilles and emblems meant for fresher eyes. The parts of Boqiao auto die cast machines are very durable and can be produced with precision, they so play a pretty important role in various facets of auto production.

Our company has sold and manufactured over 2, 000 units since 1999. Our company has a stellar standing with its customers due to our reliability and quality as well as Auto die cast customer service. The company has sold its products to Southeast Asia and Africa South America and the Middle East. Customers have also been satisfied with the service and quality. Customers need to be able to create more value.

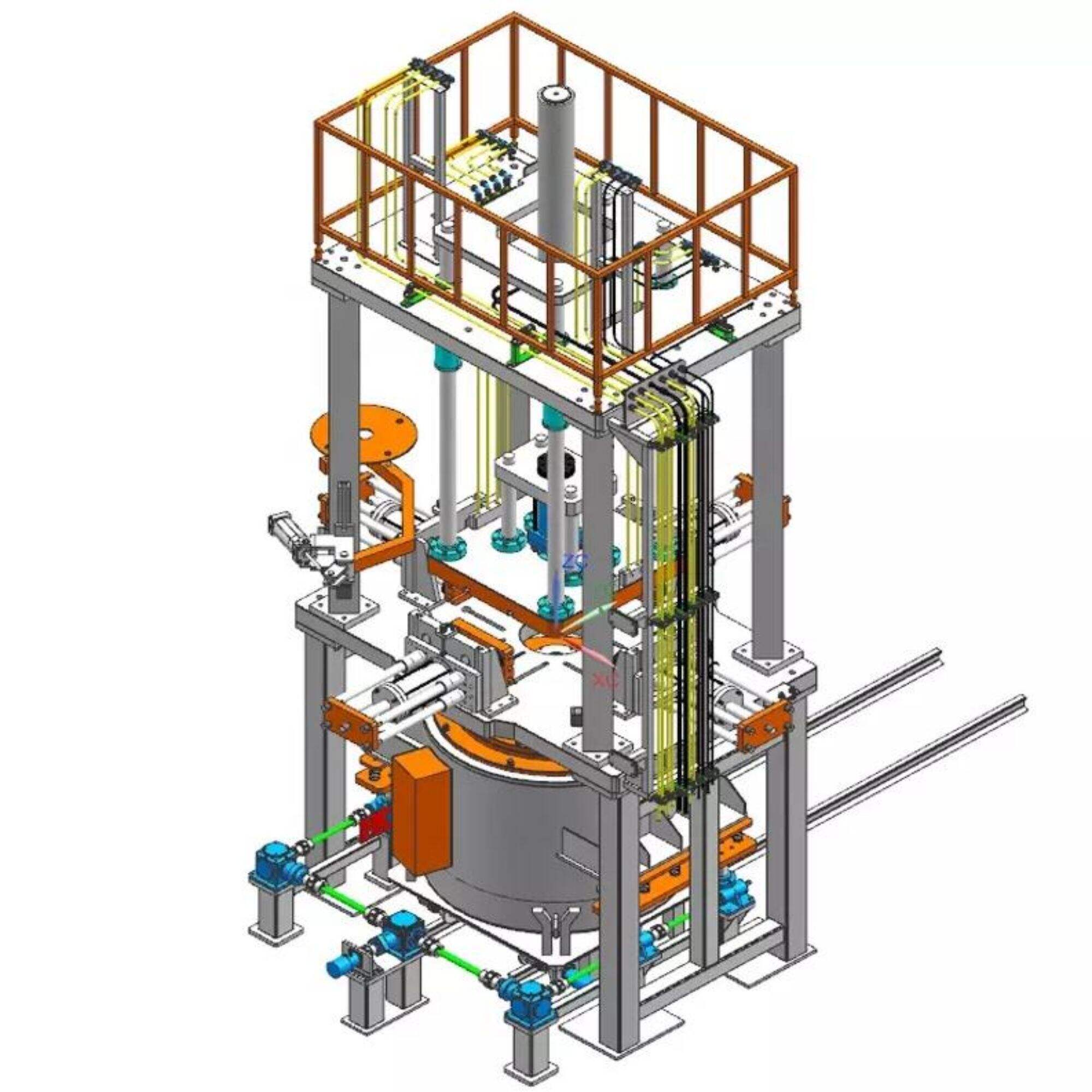

Nanjing BoQiao Machinery Co., Ltd is a Auto die cast, manufacturing, selling manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer our customers all kinds of overall solutions and turnkey projects, including technical consulting, equipment selection mold manufacturing design, process development, operating training, and more. Our products can create an added value for our customers. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.

Auto die cast gravity cast machine is a compact design, which is a perfect fit to use in a variety of manufacturing settings. Its high-performance makes for an efficient and precise casting while its user-friendly system simplifies the production process, allowing users to get the best outcomes with only minimal training. This multifaceted machine is widely employed in various industries, including motorcycle components automobile parts electric power fittings as well as engineering equipment. Its durability and cost-effectiveness make it a valuable investment for businesses seeking solid casting solutions. The machine is well-loved by customers for its dependable quality, simplicity of operation and maintenance, as well as its improved efficiency.

In 1979 we started our journey in the industry of cast iron with the purchase of casting materials This was the beginning of our experience and our presence on the market We've established lasting relationships with our clients over the years offering top-quality products and offering exceptional customer service In 1997 we expanded to include the manufacturing of industrial electric heaters This move was a strategic one that allowed us to provide more complete solutions to our clients addressing their growing demands for efficient and reliable heating equipment Our determination to provide quality and innovation distinguished us from the competition By 2002 we'd further diversified our offerings by introducing the production of casting machines This expansion allowed us to offer a wide array of casting options from materials to machinery and ensure that our customers could rely on us for all their casting needs Our vast experience and comprehensive understanding of the industry have established us as a trusted company for companies looking for top-quality casting equipment and support Since our beginning we've remained committed to continuous improvement and client satisfaction which drives us to change and evolve to the ever-changing Auto die cast